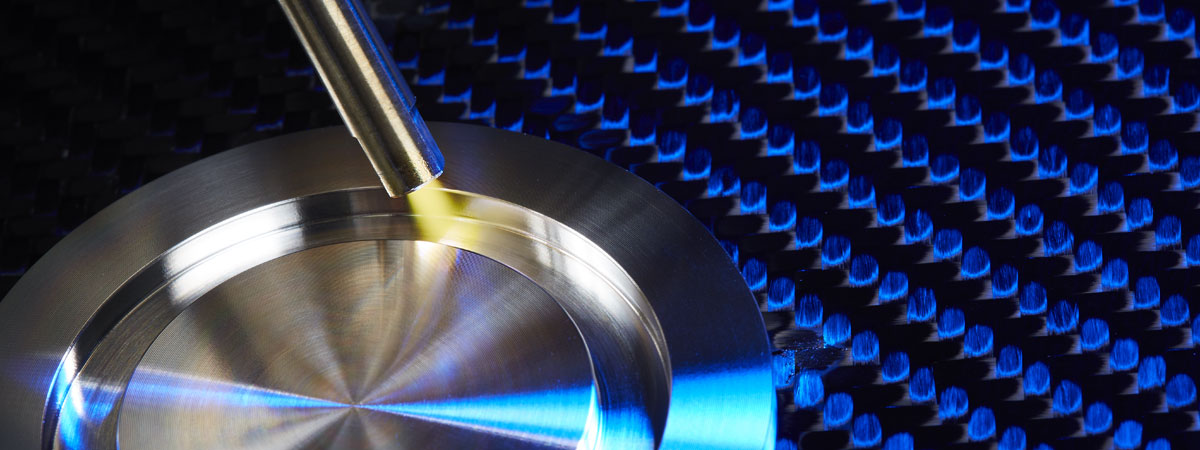

Driven by expertise

Our success is built around an exceptional body of knowledge and expertise, backed by highly trained and dedicated staff who understand your application in considerable detail.

Our standard configurations cover most applications but we understand too that no two samples or surfaces are the same. That’s why, uniquely, we offer a wide range of options that allow us to customise any standard system for your exact requirement.

Quality Assured

Designed and manufactured in the UK to ISO9001 quality standards

We achieved UKAS certification to the ISO 9001:2015 standard back in 2017, UKAS being the only recognised and government-recommended accreditation body in the UK. The certification confirms that Henniker has developed and operates a system to continuously monitor and improve quality across its entire operations, leading to the highest levels of performance and customer satisfaction.

Quality components and accessories

We also only use quality components and accessories in our systems. We believe that using recognised and trusted brands provide assurance and long-term reliability for our customers.

Microprocessor & PLC controlled

No unreliable manual flow meters and valves. Each benchtop Henniker Plasma System is microprocessor controlled, and each Advanced System is PLC controlled guaranteeing accurate and repeatable processes, each and every time.

Respected by trusted customers

We have worked with some of the most recognisable global brand names and world-leading academic institutes.

We work hard to develop long-lasting customer relationships which in turn help us to create the best customer experience possible. Whilst, like many businesses, we measure our success in growth, our core value is developing trust between ourselves and our customers.